References

SimplyOne – Pilot production line

SimplyOne – Pilot production line

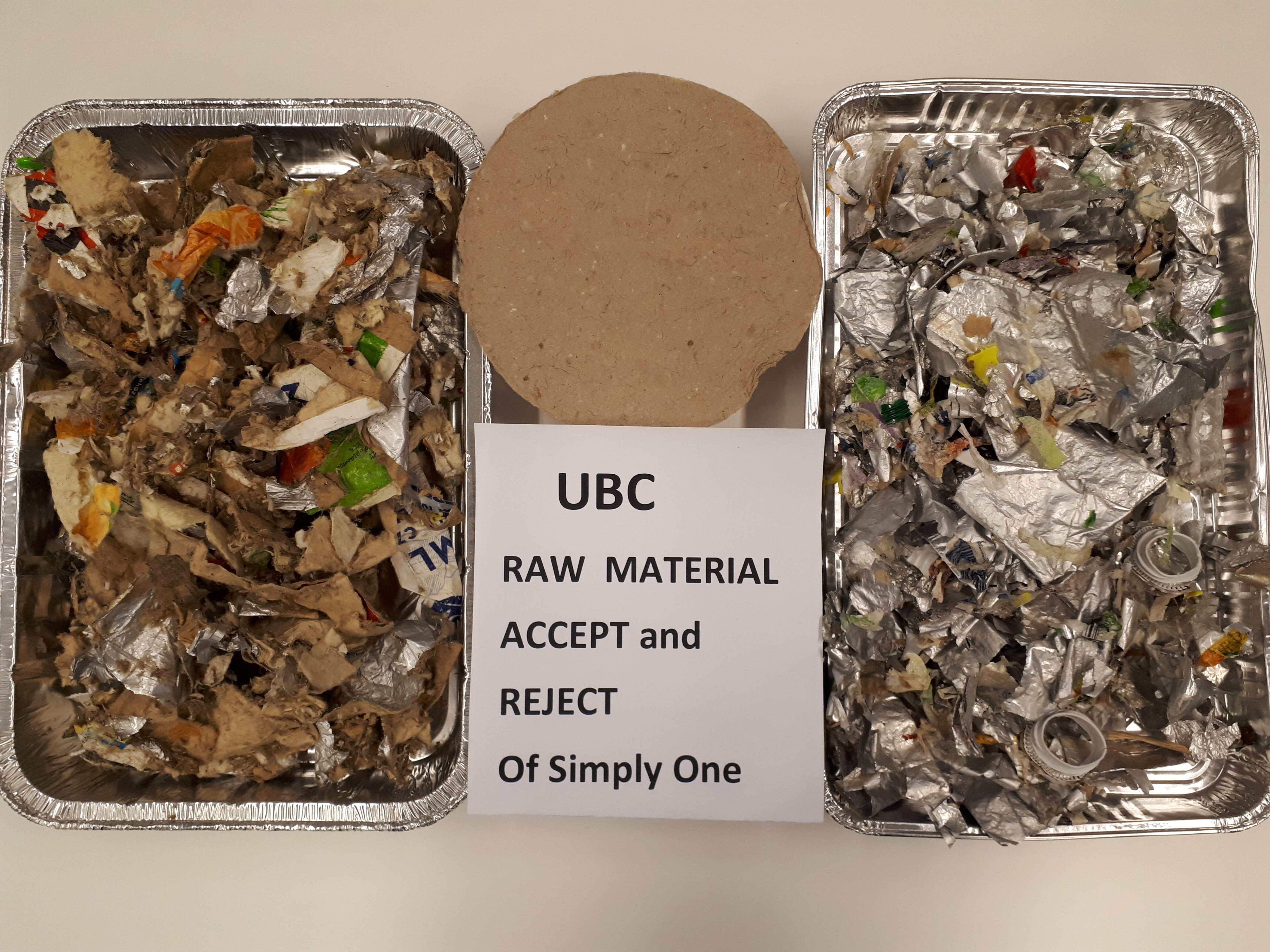

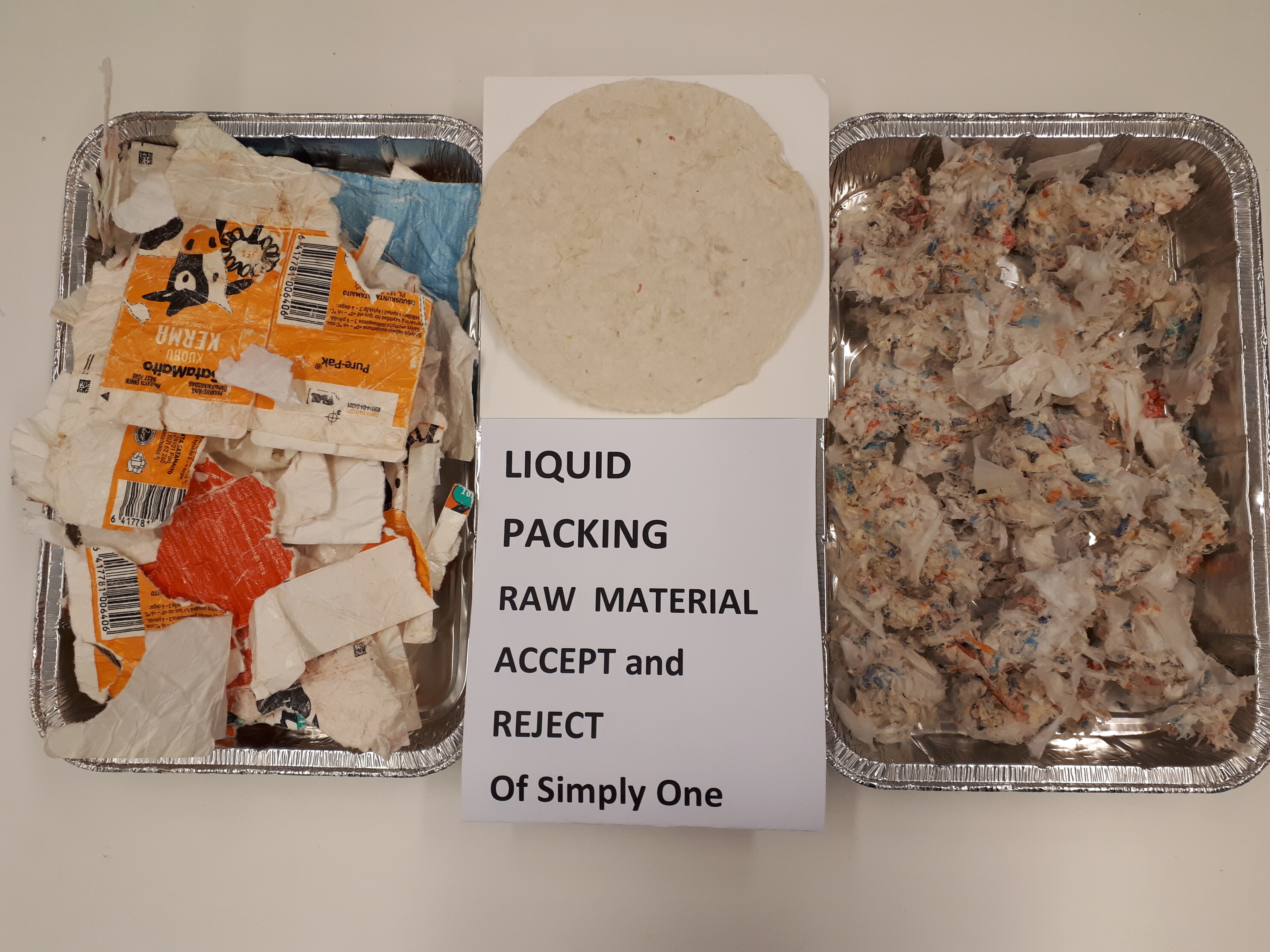

SimplyOne® Compact SOC 50 - Complete double pulper system with reject washer – Installation in Corenso Pori mill, Finland

- Capacity up to 50 tpd

- Erection completed May 2019

- Test run completed June - Aug 2019

- Raw material from Tetra Pak

- Around 30 % poly aluminum in raw material

- Clean accept fiber to fine screening

- Pure plastic and poly aluminum reject free from fibers

- Raw material from Pure-Pak

- Clean accept fiber to fine screening

- Pure plastic reject

Corenso Pori mill, Finland

Corenso Pori mill, Finland

Rebuild of 500 t/d double pulper system by SimplyOne® process

- Rebuild of existing double pulper system by SimplyOne® Add-On process

- New SimplyOne® rotor unit to secondary pulper and new process connecting piping

- Running since February 2019

- Guarantee test run successfully completed and fiber recovery targets met

- Rebuild of primary pulper rotor Ø 2,7 m

- New SimplyOne® screen plates

- Delivery completed June 2019

- Clear capacity improvement by SimplyOne® Add-On process.

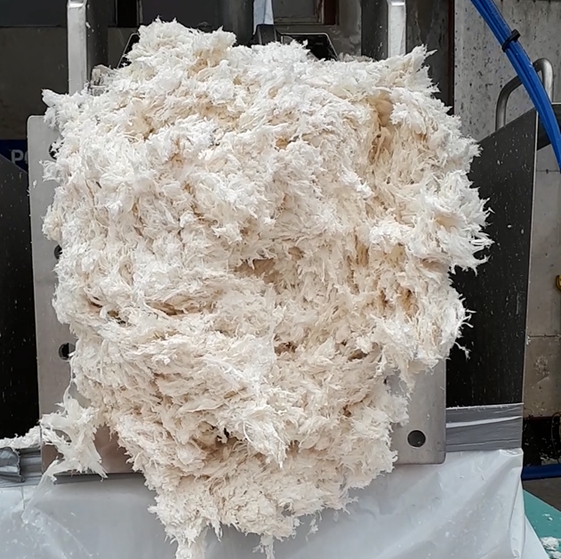

- Reject free from fibers

- Reject free from flakes

Classified customer, Finland

Classified customer, Finland

Rebuild of HC-pulper lower rotor by new SimplyOne® Rotor

- New SimplyOne® Rotor

- Rotor in operation since June 2019

Pankaboard – Lieksa mill, Finland

Pankaboard – Lieksa mill, Finland

Rebuild of reject handling system by new SimplyOne® Compactor

- New SimplyOne® Compactor

- Succesful 72 h test run together with new SimplyOne® Fiber Yield washer in the mill production line

- Compactor in operation since autumn 2018

- Tested with plastic material

- Production 10-15 ADMTPD

- Reject dryness over 70 %

- Plastic reject clean from fibres

Räpina Paper mill, Estonia

Räpina Paper mill, Estonia

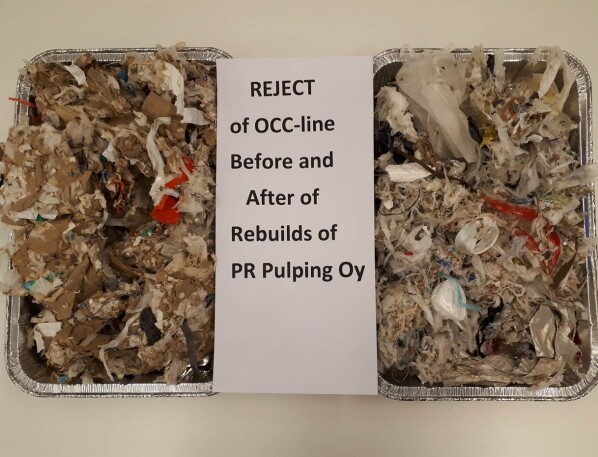

Rebuild of double pulper OCC line

- Capacity increase by 30 % up to 65 ADTPD

- Rebuild of existing pulpers

- New SimplyOne® Fiber Yield reject washer

- Machine screen basket

- Re-arrangement of pressure screening

- Delivery Sep 2019

Corenso United Oy Pori - OCC fine screening

Corenso United Oy Pori - OCC fine screening

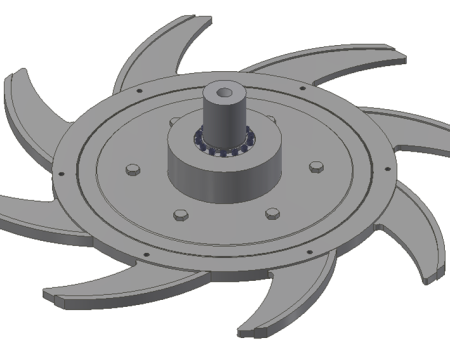

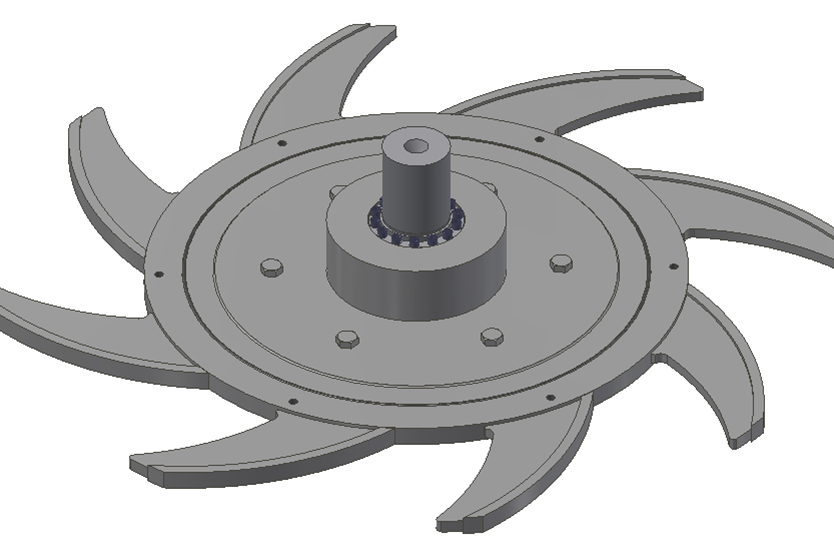

SimplyOne® SOSR 1200 screen rotor

- Design that does not allow plastics to get caught on the rotor

- Rotor design prevents thickening on the screening surface and provides more opportunities for the fiber to pass through the screening surface

- Lower fiber loss

- Rotor in operation since June 2020

SimplyOne® SOPV 20 pulper

SimplyOne® SOPV 20 pulper

SimplyOne® SOPV 20 pulper for bale pulp

- SimplyOne® pulper SimplyOne® SOR 1250 with rotor unit and narrow slotted screen plate

- Rotor unit equipped with V-belt drive

- Delivery in November 2020

- Commissioning in December 2020

SimplyOne® SOPV 8

SimplyOne® SOPV 8

Vertical pulper for baled pulp

- Pulpre volume 8 m3

- Pulp consistency 4 %

- SimplyOne® rotorunit with SOR 650 narrow slotted screen plate

- Rottor equipped with V-belt drive

- Start-up in February 2021